Electricity in Manufacturing: Driving Automation and Efficiency

Electricity in Manufacturing: Driving Automation and Efficiency. Manufacturing is undergoing a rapid transformation, driven by automation, artificial intelligence (AI), robotics, and data analytics. At the heart of this revolution is electricity, powering everything from precision machinery to smart factories. As industries shift toward greater efficiency, sustainability, and productivity, reliable and cost-effective electricity becomes more crucial than ever. This article explores the role of electricity in modern manufacturing, how automation is reshaping production, and the energy challenges industries face.

The Role of Electricity in Modern Manufacturing

Electricity is the lifeblood of modern manufacturing, enabling:

✔️ Automation & Robotics – Smart production lines, robotic arms, and AI-driven machines.

✔️ Precision Machining – CNC machines, laser cutters, and 3D printing.

✔️ Data-Driven Decision Making – IoT-connected sensors, predictive maintenance, and real-time analytics.

✔️ Sustainable Production – Energy-efficient motors, electric heating, and renewable-powered factories. From automotive assembly lines to pharmaceutical plants, manufacturers are electrifying their operations to improve speed, consistency, and quality.

How Electricity is Driving Automation & Smart Factories

The shift toward Industry 4.0 (the Fourth Industrial Revolution) is accelerating automation in manufacturing, powered by electricity. Key trends include:

1. Robotics & AI-Driven Automation

🔹 Robotic arms in automotive and electronics industries improve precision and speed.

🔹 AI-powered robots handle complex assembly tasks, quality control, and logistics.

🔹 Cobots (Collaborative Robots) work alongside humans, enhancing productivity.

2. IoT & Smart Manufacturing

🔹 Connected sensors & real-time monitoring track machine performance, reducing downtime.

🔹 Predictive maintenance prevents failures by using AI to detect potential issues.

🔹 Digital twins simulate production processes to optimize energy use.

3. Electric Vehicles (EVs) in Logistics

🔹 Automated Guided Vehicles (AGVs) transport materials in warehouses.

🔹 Electric forklifts & trucks reduce fuel costs and carbon emissions.

🔹 AI-optimized routing minimizes energy use in logistics operations.

4. 3D Printing & Additive Manufacturing

🔹 Electric-powered 3D printers create complex parts with minimal waste.

🔹 Custom manufacturing reduces lead times and enhances flexibility.

5. AI & Machine Learning for Energy Optimization

🔹 AI-driven energy management systems optimize power use in real time.

🔹 Smart grids and automated lighting, cooling, and heating reduce energy waste.

Energy Challenges in Manufacturing

Despite advancements, manufacturers face significant electricity-related challenges, including:

1. Rising Energy Costs

🔹 Manufacturing is one of the largest energy-consuming sectors, with electricity costs making up 20-40% of operational expenses.

🔹 Factories must invest in energy-efficient motors, smart grids, and AI-driven power management to stay competitive.

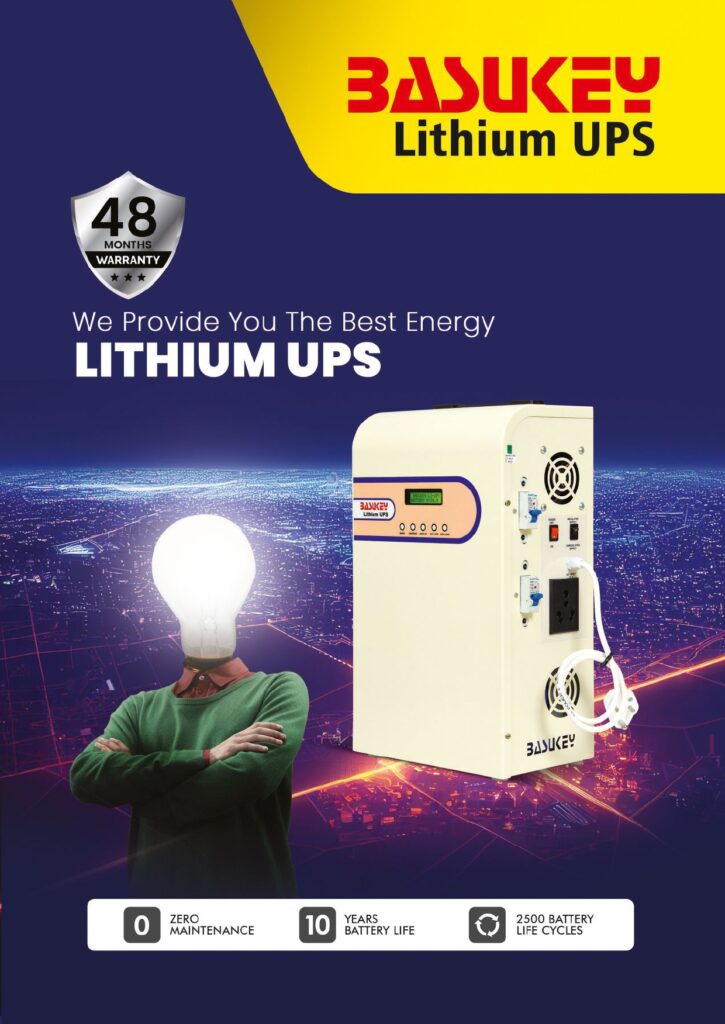

2. Grid Reliability & Downtime Risks

🔹 Power outages and voltage fluctuations can cause production losses and damage sensitive equipment.

🔹 Many industries are adopting backup power systems, microgrids, and battery storage to ensure stability.

3. Transitioning to Renewable Energy

🔹 Many manufacturers are shifting from fossil fuels to solar, wind, and hydrogen power.

🔹 On-site solar panels and battery storage help reduce electricity bills.

4. Electrification of Heat & Industrial Processes

🔹 High-temperature processes (e.g., metal smelting, chemical production) traditionally rely on fossil fuels.

🔹 Electric furnaces, heat pumps, and induction heating are emerging as clean alternatives.

The Future of Electricity in Manufacturing

The next decade will see even greater dependence on electricity in manufacturing, with advancements such as:

✅ AI-powered smart grids balancing electricity demand.

✅ Next-gen batteries & energy storage reducing reliance on unstable grids.

✅ Hydrogen-powered industrial processes cutting carbon emissions.

✅ Autonomous factories reducing human intervention.

✅ Sustainable electrification with 100% renewable-powered manufacturing.

Manufacturers who embrace electrification, automation, and efficiency will lead the future of industrial production.

Final Thoughts

Electricity is not just a power source—it’s the driving force behind automation, smart manufacturing, and sustainable production. As industries shift towards AI-driven, energy-efficient, and electrified operations, the manufacturing sector will continue to evolve and innovate.